Selected Experience

Blood Oxygenator Development

I worked with an elite group of cardiothoracic surgeons to analyze and improve blood oxygenators – a disposal medical device used to oxygenate blood during surgeries. Our goal was to improve these oxygentors to last for several weeks, allowing patients with end stage lung failure to survive until their affliction heals or a donor lung became available.

Designed and built equipment to produce prototypes of artificial organs and surgical devices

Assisted with long term animal surgical studies, including administering medications and providing nursing care to animal subjects.

Prepared and analyzed surgical devices after animal trials

Designed and fabricated equipment necessary to manufacture prototype blood oxygenators

Planned and supervised laboratory research performed by undergraduate, high school students.

Designed and built equipment as part of a team that allowed the development of a surgical technique that saved approximately 400 US military personnel in Iraq and Afghanistan.

Microfluidic Cell Culturing System

Developed a microfluidic system to miniaturized scientific experiments onboard the International Space Station. My work included the development of cell sorting apparatus within a glass slide. These apparatuses were fabricated using photolithography followed by acid etching.

Corrosion Resistance and Thin Film Heater for Aerospace Operations

In order to carry out scientific experiments onboard the International Space Station, complex and custom-made components were fabricated using 3D printing techniques. However, the corrosive solvents and reagents used within these experiments degraded the surfaces of the 3D components.

I developed a technique to allow very thin films of glass to be deposited on the surfaces of complex geometries, preventing damage to the underlying component. The thinness of this coating did not interfere with the geometric tolerances of these components and the clarity allowed various measurements to be conducted unimpeded.

I also developed a method for depositing thin layers of conductive material on the surfaces of, and within, these 3D printed components, allowing precise temperature control remotely from Earth.

Lined Oilfield Hose

In partnership with a oilfield service company, I developed a pilot extrusion to produce a large diameter, flexible hose capable of transporting crude oil, natural gas and water at the same time. As this hose could lay flat, it took up much less storage space.

This hose was manufactured using a co-extrusion process whereby a flexible, but corrosion resistant plastic lined the inner bore of the hose. The exterior was surrounded by a tougher rubber, allowing the hose to maintain flow of high-pressure liquid.

Mercaptan Removal from Natural Gas Liquids

Due to increasingly rigid environmental standards, a legacy gas plant was no longer able to market the propane, butane and other liquids recovered from natural gas due to the prohibitively high levels of mercaptans.

Existing processes within the plant were designed decades before current environmental standards took effect and would be prohibitively expensive to retrofit.

I designed a process to inexpensively strip this mercaptans from the natural gas stream, allowing sales of natural gas liquids to be re-established.

Plasma Reactor

I developed a room temperature plasma reactor to treat vapors from a process stream, effectively oxidizing hydrocarbon contaminants, allowing for atmospheric discharge.

This plasma reactor was fabricated using a corona discharge setup whereby a high voltage was applied across an insulator to produce a plasma.

Automated Weld Position Determination

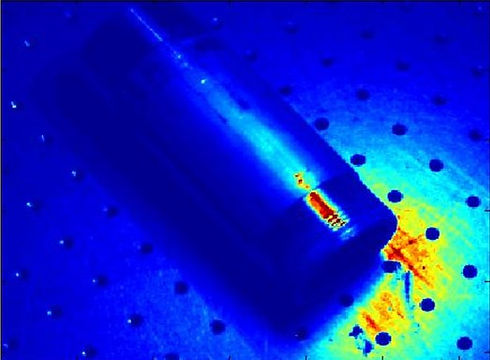

Working with General Electric, our team developed a technique to determine the position of weld bead on welded pipe. During formation of electrically welded pipe a sheet of metal is folded and the ends welded to form a tube. Afterwards, the bead is ground, making location difficult.

General Electric developed a machine to inspect this weld bead via X-ray, however finding the position of this weld was very difficult, particularly after painting or surface treatment of the pipe.

Using infrared imaging, followed by various mathematical filters, a system to reliably find this bead was developed.

Hollow Fiber Production

Industrial filtration process requiring the removal of particulates below 5 micrometers in size is typically done through a process known as microfiltration or nanofiltration. These processes most often employ plastic tubes with outer diameters of less than 2 or 3 millimeters. Known as hollow fiber membranes, the wall of these tubes contain very small pores that act as the filtering media.

As microfiltration is widely used to clarify beverages, food, industrial liquids and gasses, a significant demand exists for these hollow fiber membranes.

The most commonly used method for producing these hollow fiber membranes involves the use of a room temperature extrusion process. An alternative process exists whereby the the membrane is extruded from a high-temperature melt.

This later production method is more complex, but produces a higher strength membrane, allowing much high operating pressures and with it, more efficient filtration.

My partners and I developed a system to produce this fiber via the hot-melt process in order to supply the market with thermally extruded hollow fiber.

Removal of Suspended Solids from Oilfield Produced Water

Matador Resources, an oil and gas producer in the Southwest USA was spending large amounts of money to dissolve particulates suspended in the produced water accompanying oil production. These particulates clogged disposal wells, significantly decreasing their capacity and lifetimes.

I developed a process to continuously filter particulate, which was found to be 95% cheaper than the previously employed chemical treatments. This particulate was then de-watered and landfilled.

Elimination of Solids Buildup in Oilfield Pipeline

Matador Resources found that the capacity of pipelines used to conduct produced water continually decreasing until a chemical flush costing several hundred thousand dollars per pipeline was required. The frequency and effectiveness of these chemical flushes continued to increase until capacity reached critically low levels.

I established a field lab to analyze these particulates and determined that the suspended particulates behaved as a slurry. The flow rate within these pipes was below the critical level required to maintain the suspension of the particulates. As a result, the particulates began to precipitate, the resulting buildup reduced the capacity of pipelines.

After the installation of the high pressure pumps which forced a higher flow through the lines, scouring buildup of particulates and renewing the original capacity of the lines.